With battery prices dropping, an end to battery shortages on the horizon, and unprecedented deployment predicted over the next six years, the energy industry is likely at or near the tipping point for energy storage from pilot projects to prime time. As the size of the storage systems grow and the market matures, the criteria for how to house critical battery assets are also evolving. The container solution started out strong with its features of convenience, lower cost and modularity. However, because of its strengths in areas like safety, operational efficiencies, and system flexibility, the building envelope is no longer the storage underdog. From the outset, which solution will win possession of the batteries is no longer predictable.

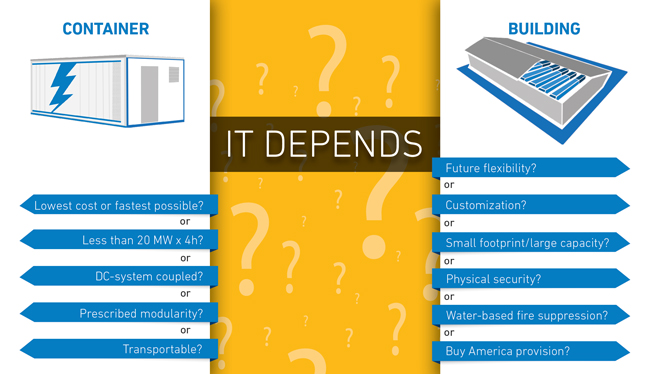

After evaluating 150+ energy storage (ES) projects, we have developed the following benefits analysis framework to help decision-makers identify, establish and prioritize decision criteria and evaluate their options to determine which solution—container or building—“best” fits when it comes to the specific needs of the project, the site, and, of course, the customer.

Permitting and site constraints

Perhaps no set of criteria results in the dreaded “It depends” more than permitting issues. Aesthetics, exterior landscaping and physical plant security requirements are becoming increasingly prevalent and may preclude a container solution.

Physically restricted sites or the need for greater energy density also favor the building solution. For example, for the same 100 MWh storage capacity, a container solution will have a footprint of/require approximately 40,000 square feet but a building will require about 20,000 sf—less with a two-story building.

Having a storage or maintenance building classified as “occupied” is a common permitting concern because this designation can trigger multiple unwanted permitting challenges, involving ADA access, offices, bathrooms, site utilities, and other additions. When building officials deem containers to be “habitable” facilities rather than pieces of equipment or electrical rooms, the permitting for containerized solutions could become more complex than a building solution.

Thermal management

Ensuring that the batteries stay within their safe operating parameters is essential for warranties and performance guarantees and to prevent unwanted thermal events. Containerized systems have physical limits to their thermal management systems that constrain these systems in terms of size, efficiency, flexibility of controls, and life/resiliency. In contrast, a building solution offers significantly greater ability to customize airflow to critical areas, control humidity, and modify the system for future use cases. System backup, resiliency, and HVAC augmentations are also more easily achieved with a building solution.

Fire suppression

Fire risk is a top concern in any energy storage project. With the release of NFPA 855 in September 2019, the energy storage market is working diligently to forecast and address the impacts this standard will have on projects for both containers and buildings. Water-based suppression is regarded as the most effective fire suppressant for lithium ion modules. Water-based systems are currently easier to deploy and less likely to fail in a building than in a group of containers. However, thanks to standards development, coupled with engineering methods, implementation methods for fire suppression are advancing quickly. When water supply is a concern, appropriately sized water supply tanks can be installed in remote areas with either configuration. Requiring water-based suppression systems in containers may level this differentiator between container and building solutions.

As an added level of operational monitoring, the visual confirmation of system issues (which many operators prefer) is more efficiently implemented in a building.

Augmentation efficiencies

Augmenting the ES system is easier in a building, especially for projects with lifetimes greater than 10 years and situations in which initial oversizing of the battery system is not cost-effective. Building solutions also allow a greater ability to augment thermal management if capital expenditures need to be mitigated and battery degradation is more aggressive than anticipated.

Together, the easier access and augmentation options of the building solution combine to increase safety, reduce the amount of land required, and address comfort for operations and maintenance (O&M) staff. Just as critical, we’ve seen these efficiencies decrease system downtime and maximize revenue, particularly when energy contracts are tight.

Weather mitigation

Unsurprisingly, buildings are typically a more effective means to mitigate weather impacts to an energy storage system. Specific building solution advantages include employee safety, flexibility of fire risk mitigation (discussed earlier) battery delivery logistics/storage, and construction/operational productivity. For example, building solutions can provide immediate secure and temperature-controlled storage for pallets of battery modules. They also offer a safer work environment during both construction and operational service and maintenance activities, where extreme weather (either cold or hot) adds to the hazards of tasks such as racking battery modules.

General operational & maintenance efficiencies

To illustrate the maintenance issues between these solutions, let’s compare two recent projects with 40 MWh storage capacity.

- Project 1 consists of 10 weather-resistant steel containers next to a remote substation. Each container has 20 doors, 20 locks, 8 individual HVAC units mounted within some of the doors, and approximately 500 lineal feet of weather stripping and seals, for a total of 200 doors, 200 locks, 80 HVAC units, and almost a lineal mile of weather stripping and seals.

- Project 2 is a 10,000-square-foot pre-engineered metal building in an industrial park. The building has seven doors and locks, 100 lineal feet of weather stripping and seals, two ground-mounted air handling units and two condensing units and associated balance of plant.

No matter the solution, any opening is subject to moisture intrusion and failure of seals, hinges, and locks, as well as other equipment. A failure mode comparison of these two projects will favor the building.

Compared with containers, building solutions also provide greater control over the structural envelope, as well as thermal and moisture protection. In addition to lower maintenance concerns, building solutions also provide a better-insulated space. Given the relatively fixed ISO dimensional standards for containers, there are limitations on the amount of insulation, potentially requiring more run-time on thermal management systems due to exterior “skin” heat gains when the batteries aren’t active. In addition to general maintenance efficiencies, buildings offer an increased ability to holistically integrate controls, fault detection, diagnostics, and service calls to the human-machine interface. They also often allow greater flexibility in voltage, system customization, and use case optimization.

Access efficiencies

Clearer access to the battery modules affects operational efficiencies as well as workplace safety and maintenance costs. High-quality, 24/7 workspace access to the battery modules is easier to design into a building solution compared with a container, an advantage that may be more prominent in regions with more extreme climatic conditions.

Future-proofing

Technology tomorrow will look different than it does today. Compared with container solutions, buildings support greater flexibility for system modifications and future use cases. The container solution is well defined and might currently be more attractive purchases for follow-on owners of these systems, but that must be balanced with the value of the customization capability of building solutions.

Overall, a building solution is more flexible/adaptable should system operation parameters change in response to evolving market conditions and services.

Security

Security concerns are another inevitable aspect of a growing technological infrastructure for which containers offer little advantage. The configuration of a building is naturally more conducive to integrating standard or custom security measures. Also, similar to methods employed in the data center market, energy storage can be hidden more effectively in a building.

Cost and time horizons

Regarding time and money, a container solution has some distinct advantages. Single containers can generally be manufactured and assembled more quickly than a building, and container pricing and shipping costs may be more stable compared with regional or area differences in construction pricing. A building solution also involves more complicated and lengthier EPC processes and potentially extended permitting time, although these issues can often be mitigated with phased design and submittal processes.

However, in our experience, the container’s time advantage is not as significant as one might expect. The aforementioned building in Project 1 was located in an urban area, and the container in Project 2 on a remote site. Despite Project 1’s rigorous urban permitting requirements, the building project took only 11 months to complete, compared with eight months for the container project.

Also, due to higher maintenance requirements over the long term, the container’s O&M costs will catch up to the building’s over time.

Rules of thumb

In specific and rare cases, the choice between a building and a container solution can be straightforward:

- DC system coupling or prescribed modularity—Both of these situations require a containerized solution.

- Small capacity projects—Storage needs under 20 megawatts by four hours are probably best achieved through containers. Should battery energy density increase 2–3x current values, this figure will shift further in the container’s favor.

- Uncertainty in market conditions in some regions favors containers to ensure assets can be redeployed to more economically advantageous regions.

- Steel tariff mitigation—The most cost-effective containers are currently assembled overseas. As the debate on tariffs continues and as “Buy American” provisions develop, projects are more likely to benefit from a building solution.

- Larger capacity projects or very constrained parcels—Projects that require higher energy densities in a given footprint benefit from a building solution.

- A battery storage building can serve a dual role as an O&M building if desired.

- Tax incentives and depreciation can tip a project in either direction, depending on the project’s jurisdiction.

- The operational mindset is different for a container vs. a building, but neither solution should be considered “set and forget.”

Strategizing solutions

When evaluating enclosure solutions for battery energy storage, many factors need to be considered before deciding which one ultimately has the home court advantage. The container solution still dominates when modularity, price and transportability are the key determinants. However, the building solution’s adaptability makes it a worthy competitor. Occasionally, regional market, permitting and regulatory conditions help one solution edge out the other. But when the choice is not immediately clear, the trade-offs in this framework can simplify the decision between building vs. containers in today’s fast-moving market and regulatory environment.